Pursuing Safe and Efficient Recycling of Lithium‑Ion Batteries

Lithium-ion batteries are serving today as a gateway to the clean energy world called for by climate change. But lithium-ion batteries — which commonly contain raw materials in limited supply, such as lithium and cobalt — face sustainability issues of their own.

Recycling helps to mitigate these issues. That’s why the Electrochemical Safety Research Institute (ESRI) is collaborating with Dr. Pulickel Ajayan‘s team at Rice University in Houston to develop lithium-ion battery recycling processes that will reduce the need for mining and manufacturing new raw materials and alleviate related economic, environmental, and ethical concerns.

“To be sustainable, the lithium-ion battery industry must have an efficient and economically viable recycling component that requires minimal amounts of chemicals and energy,” said Dr. Taina Rauhala, ESRI research scientist. “Recycling lithium-ion batteries is important both to conserve natural resources and to contribute toward a circular economy. We aim to develop an effective hydrometallurgical process that will recover the valuable metals in used lithium-ion cells and keep them out of the waste stream.”

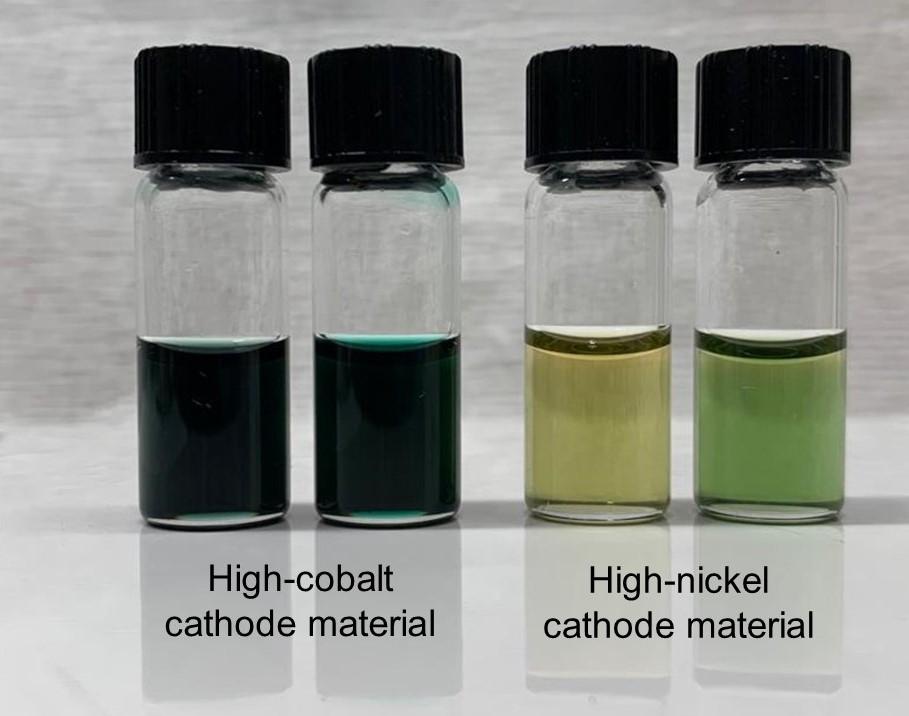

The ESRI and Rice University collaboration studies the efficiency of using less hazardous chemicals for the leaching process used to recover metals for recycling. Team members are researching two different solutions to extract valuable lithium-ion battery metals — nickel, cobalt, lithium, and manganese — from the battery cathodes. The research compares a state-of-the-art hydrometallurgical process that uses sulfuric acid for leaching to a process developed at Rice University, which uses a less hazardous combination of substances called a “deep eutectic solvent” that consists of a mixture of choline chloride and ethylene glycol.

ESRI and Rice University will next expand the project’s scope, focusing on the scalability of these recycling processes, optimization of the metal recovery processes, and the characterization and optimization of regenerated batteries.

Revolutionizing Safety Through Science

At UL Research Institutes, we tackle tough issues with a scientific rigor trusted throughout the world.